Tests on Building Stones

The building stones are to be tested for their different properties. Following are such tests for the stones:

(1) Acid test

(2) Attrition test

(3) Crushing test

(4) Crystallization test

(5) Freezing and thawing

(6) Hardness test

(7) Impact test

(8) Microscopic test

(9) Smith's test

(10) Water absorption test.

1. Acid test -

This test is carried out to understand the presence of calcium carbonate in building stone. A sample of stone weighing about 50 to 100 gm is taken. It is placed in a solution of hydrophobic acid having strength of one percent and is kept there for seven days. Solution is agitated at intervals.

A good building stone maintains its sharp edges and keeps its surface free from powder at the end of this period. If the edges are broken and powder is formed on the surface, it indicates the presence of calcium carbonate, and such a stone will have poor weathering quality. This test is usually carried out on sandstones.

2. Attrition test -

Attrition test is done to find out the rate of wear of stones, which are used in road construction. The result of the test indicates the resisting power of stones against the grinding action under traffic.

The following procedure is adopted:

Samples of stones is broken into pieces about 60mm size.

Such pieces, weighing 5 kg/50 N are put in both the cylinders of Devil’s attrition test machine. Diameter and length of cylinder are respectively 20 cm and 34 cm.

Cylinders are closed. Their axes make an angle of 30 degree with the horizontal.

Cylinders are rotated about the horizontal axis for 5 hours at the rate of 30 rpm.

After this period, the contents are taken out from the cylinders, and they are passed through a sieve of 1.5mm mesh.

Quality of material which is retained on the sieve is weighed.

Percentage wear worked out as follows:

Percentage wear = (Loss in Weight/Initial Weight) x 100

3. Crushing test -

Samples of stone is cut into cubes of size 40 x 40 x 40 mm sizes of cubes are finely dressed and finished. Maximum number of specimens to be tested is three. Such specimen should be placed in water for about 72 hours prior to test and therefore tested in saturated condition. Load bearing surface is then covered with plaster of Paris of about 5mm thick plywood. Load is applied axially on the cube in a crushing test machine. Rate of loading is 13.72 N/mm²(140 kg/sq.cm) per minute.

Crushing strength of the stone per unit area is the maximum load at which the sample crushes or fails divided by the area of the bearing face of the specimen.

4. Crystallization Test -

In this test, at least four cubes of stone with side as 40mm are taken. They are dried for 72 hrs. and weighed. They are then immersed in 14% solution of Na2SO4 for 2 hours. They are dried at 100 degree C and weighed. Difference in weight is noted.

This procedure of drying, weighing, immersion and reweighing is repeated at least 5 times. Each time, change in weight is noted and it is expressed as a percentage of original weight.

It is to be noted that crystallization of CaSO4 in pores of stone causes decay of stone due to weathering. But as CaSO4 has low solubility in water, it is not adopted in this test.

5. Freezing and thawing test -

Stone specimen is kept immersed in water for 24 hours. It is then placed in a freezing machine at -12 deg C for 24 hours. Then it is thawed or warmed at atmospheric temperature.

This should be done in shade to prevent any effect due to wind, sun rays, rain etc. this procedure is repeated several times, and the behavior of stone is carefully observed.

6. Hardness Test -

For determining the hardness of a stone, the test is carried out as follows:

A cylinder of diameter 25mm and height 25mm is taken out from the sample of stone. It is weighed.

The sample is placed in Dorry’s testing machine, and it is subjected to a pressure of 12.50 N.

Annular steel disc machine is then rotated at a speed of 28 rpm.

During the rotation of the disc, coarse sand of standard specification is sprinkled on the top of disc.

After 1000 revolutions, specimen is taken out and weighed.

The coefficient of hardness is found out from the following equation:

Coefficient of hardness = 20 – (Loss of weight in gm/3).

A mineral's hardness is a measure of its relative resistance to scratching, measured by scratching the mineral against another substance of known hardness on the Mohs Hardness Scale.

The Mohs Hardness Scale is used as a convenient way to help identify minerals.

7. Impact Test -

To determine the toughness of stone, the impact test is carried out in a Page Impact Test Machine as follows:

A cylinder of diameter 25mm and height 25mm is taken out from the sample of stones.

It is then placed on cast iron anvil of machine.

A steel hammer of weight 2 kg is allowed to fall axially in a vertical direction over the specimen.

Height of first blow is 1 cm, that of second blow is 2 cm, that of third blow is 3 cm and so on.

Blow at which specimen breaks is noted. If it is nth blow, ‘n’ represents the toughness index of stone.

8. Microscopic Test -

In this test, the sample of the store is subjected to microscopic examination. The thin sections of stones are taken and placed under the microscope to study the various properties such as :

Average grain size

Existence of pores, fissures, veins and shakes

Mineral constituents

Nature of cementing material

Presence of any harmful substance

Texture of stones etc.

9. Smith's test -

This test is performed to find out the presence of soluble matter in a sample of stone. Few chips or pieces of stone are taken, and they are placed in a glass tube. The tube is then filled with clear water. After about an hour, the tube is vigorously stirred or shaken.

Presence of earthy matter will convert the clear water into dirty water. If water remains clear, stone will be durable and free from any soluble matter. On other hand, if the water becomes dirty, it will indicate that the stone contains too much of soluble earthy and mineral matters.

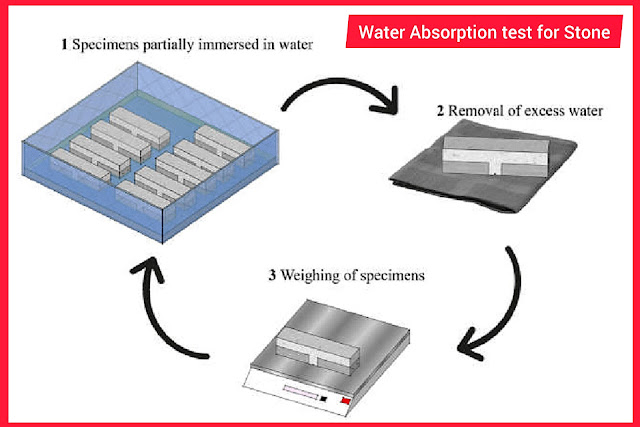

10. Water Absorption Test -

The test is carried out as follows:

From the sample of stone, a cube weighing about 50gm is prepared. Its actual weight is recorded as W1 gm.

Cube is then immersed in distilled water for a period of 24 hrs.

Cube is taken out of water and surface water is wiped off with a damp cloth.

It is weighed again. Let the weight be W2 gm.

Cube is suspended freely in water and its weight is recorded. Let this be W3 gm.

Water is boiled and cube is kept in boiling water for 5 hours.

Cube is removed and surface water is wiped off with a damp cloth. Its weight is recorded. Let it be W4 gm.

From the above observations, values of the following properties of stones are obtained:

Percentage absorption by weight after 24 hours = (W2 – W1) x 100 / W1

Percentage absorption by volume after 24 hours = (W2 – W1) x 100 / (W2 – W3)

[ ·.· Volume of displaced water = W2 – W3]

Percentage porosity by volume = (W4 – W1) x 100 / (W2 – W3)

Density =W1 / (W2 – W3) kg/m3

Specific Gravity = W1 / (W2 – W3)

Saturation Coefficient = (Water Absorption/Total Porosity) = (W2 – W1) / (W4 – W1)

Comments

Post a Comment

Leave your comment