Methods of Soil investigation or Soil exploration

- Open excavation or direct methods

- Boring or semi-direct methods

- Geophysical methods or indirect methods

1. Open excavation –

In this method of exploration an open excavation is made to inspect the soil strata.

This method can be divided into two categories:

(i) Pits and Trenches

(ii) Drifts and Shafts

(i) Pits and Trenches -

Pits and trenches are excavated at the site to inspect the strata. The size of the pit should be sufficient to provide necessary working space. IS: 4453-1967 recommends a clear working space of 1.2 m into 1.2 m at the bottom of the pit. The depth of the pit depends upon the requirement of the investigation. Shallow pits up to a depth of 3 m can be made without providing any lateral support.

For deeper pits, especially below the ground water table, the lateral support in the form of sheeting and bracing system is required. As the depth of the pit increases, its cost increases rapidly. For depths greater than 6 m bore holes are more economical than open pits.

Trenches are long shallow pits. As a trench is continuous over a considerable length, it provides exposure along a line. The trenches are more suitable than pits for exploration on slopes. Pits and trenches are excavated at the site to inspect the strata. The size of the pit should be sufficient to provide necessary working space. IS : 4453-1967 recommends a clear working space of 1.2 m into 1.2 m at the bottom of the pit. The depth of the pit depends upon the requirement of the investigation.

Shallow pits up to a depth of 3 m can be made without providing any lateral support.

For deeper pits, especially below the ground water table, the lateral support in the form of sheeting and bracing system is required.

As the depth of the pit increases, its cost increases rapidly.

For depths greater than 6 m bore holes are more economical than open pits.

Trenches are long shallow pits. As a trench is continuous over a considerable length, it provides exposure along a line. The trenches are more suitable than pits for exploration on slopes.

Test pits and trenches can be excavated manually or mechanically.

(ii) Drifts and shafts –

Drifts are horizontal tunnels made in the hill side to

determine the natural and structure of the geological formation. IS 4453 - 1980

recommends that a drift should have the minimum clear dimensions of 1.5-meter

width and 2.0 m height in hard rock. In soft rock, and arch roof is more

advantageous than a flat roof.

If the ground is unable to stand of its own, supports have to be provided to carry the load of the roof and the sides of the drift. Drifts are useful for as establishing the minimum excavation limits to reach sound rock and for locating faults and shear zones and buried channels in the river section. However, the drifts are generally expensive. These are used only when other method does not provide the required - information. Drifts are also known as adits.

Shafts are large size vertical hole made in the geological

formation. These may be rectangular or circular in section. The maximum width

of a rectangular 2.4 m and for a circular shaft the minimum the diameter is 2.4

m.

In week ground, the side of the shaft should be properly

supported. Deep shafts should be properly ventilated. Shafts are used to reach

a particular strata at a depth of 4 m or more. shafts are also used to extend

the exploration below the river bad already done by the mean of tunnels.

2. Borings -

When the depth of exploration is large, boring is used for exploration. A vertical bore hole is drilled in the ground to get the information about the sub-soil strata. Samples are taken from the bore hole and tested in a laboratory. The bore hole may be used for conducting in situ tests and for locating the water table.

Extensometers or pressure meter may also be installed in the bore hole for measurement of the deformation in the sub-strata.

Methods of boring -

Depending upon the type of soil and the purpose of boring

the following methods are used for drilling the holes.

1. Augar boring

2. Wash boring

3. Rotatory drilling

4. Percussion drilling

5. Core boring

1. Auger boring-

An auger is a boring tool similar to one used by a carpenter for boring holes in wood. It consists of a shank with a cross wise handle for turning and having Central tapered feed screw. The auger can be operated manually for mechanical.

- Hand operated augers or hand augers use in boring are about 15 to 20 CM in diameter. The depth of the holes is normally limited normally limited to a maximum of 10 m. These augers are generally suitable for all types of soil above water table but suitable only in clayey soil below the water table. Hand operated augers are not suitable in very stiff or hard clay nor in granular soils.

- Power Driven Augers or Mechanical Augers are driven by power these are used for making holes in hard strata to a greater depth. Continuous flights augers are special type of mechanical augers which are provided with a central hollow tube. The flight act as a screw conveyor to bring the soil to the surface. This method may be used in all type of soil including sandy soils below the water table but is not suitable if the soil is mixed with gravel cobbles etc. During sampling, the plug is removed, and a sampler is inserted the for taking the samples. The investigation is the quite rapidly and economically by ager boring. The main disadvantage of the auger boring is that the soil samples are highly disturbed.

2. Wash boring -

Wash boring is commonly used for boring hole holes. Wash boring is a fact and simple method for boring holes in all types of soil, but boulders and rocks cannot be penetrated by this method.

In wash boring, the

hole is drilled by first driving a case about 2 to 3 m long, and then inserting

into it a hollow drill rod with a chisel shaped chopping bit at its lower end. Water

is pump down the hollow drill road, which is known as wash pipe.

A stream of water under pressure is forced through the rod and the bit into the hole with loosens the soil as the water flows up around the pipe. The loosened soil is suspension in water is discharged into a tab. The soil in suspension settles down in the tub and the clean water follows into a sump which is reused for circulation.

The bit which is hollow is screwed to a string of hollow drill rods supported on the tripod by a rope or steel cable passing over a pulley and operated by a winch fixed on one of the legs of the tripod. The wash boring is mainly used for drill holes only. Once the hole has been drilled a sampler is inserted to obtain soil samples for testing.

The equipment used in wash boring is relatively light and in expensive.

The main disadvantage of this method is that it is slow in stiff soils and coarse-grained soils. It cannot be used efficiently in hard soils, rocks and the soils containing boulders. The method is not suitable for taking good quality and undisturbed samples above water table.

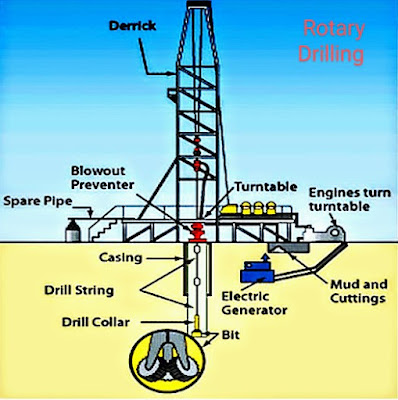

3. Rotary drilling -

In rotary drilling method, the bore hole is advanced by rotating a hollow drill road which has a cutting bit at its lower end. A drill head is provided at the top of drill road. It consists of a rotatory mechanism and an arrangement for applying downward pressure.

As the drilling road is rotated, the cutting bit shears off chips of the material penetrated. A drilling fluid under pressure is introduced from the bottom of the hole to the ground surface through an angular space between the drilling rod and the wall of the hole. The drilling fluid also cools the drilling bit. In case of uncased hole, the drilling flood also supports the walls of the hole.

When the soil sample is required to be taken the drilling rod is raised and the drilling bit is replaced by a sampler.

Rotatory drilling can be used in clay, sand and rocks. Boring holes diameter 50 mm to 200 mm can be easily made by this method. The method is not well adopted for use in material containing a large percentage of particles of gravel size and larger because it becomes difficult to advance the hole.

4. Percussion drilling -

The

percussion drilling method is used for making holes in rocks, boulders and

other hard strata. In this method, a heavy chisel is alternately lifted and

dropped in a vertical hole. The material gets pulverized.

If the point where the chisel strikes is above the water table, water is added to the hole. The water forms a salary with the pulverized material which is removed by a sand pump. Percussion drilling may require a casing. Percussion drilling is also used for drilling of tube well.

The main advantage of percussion drilling method is that it

can be used for all type of materials. It is particularly useful for drilling

holes in glacial till containing boulders.

One of the major disadvantages is that the material at the bottom of the hole is disturbed by heavy blows of the chisel. It is not possible to get good quality and undisturbed sample. This method is generally more expensive than other methods.

5. Core drilling -

The core drilling method is used for drilling holes and for obtaining rock cores. In this method, a core barrel fitted with a drilling bit, is fixed to a hollow drilling rod. Water is pumped continuously into the drilling rod to keep the drilling bit cool and to carry the disintegration material to the ground surface.

The core drilling may be done using either a diamond studded bit or a cutting edge consisting of chilled shot. The diamond drilling is superior to the other type of drilling but is costlier. The core barrel may consist of a single tube or a double tube. A double tube barrel gives a good quality sample of the rock.

Geophysical method -

Geophysical methods are used in preliminary investigations

of sub soil strata. The methods can be used for the location of different

strata and for a rapid evaluation of the sub soil characteristics however, the

methods are very approximate for detailed and reliable investigations the

conventional methods of driving a whole taking a sample and test it the

geophysical methods can be divided into two categories:

(A) Seismic method

(B) Electrical resistivity method.

(A). Seismic methods or seismic refraction methods -

The seismic methods are based on the principle that the elastic shock waves have different velocities in different materials. At the interface of two different materials the waves get reflected and partly refracted.

Seismic methods of sub surface exploration generally utilize the refracted waves. The shock wave is created by a hammer blow or by a small explosive change at a point P. The shock wave travels through the top layer of the soil or rock with a velocity(v1) and depending upon the type of material in layer 1.

The observation of the first arrival of the waves is recorded by geophone locate it various point such as A, B, C. The geophones convert the ground vibration into electrical impulses and transmit them to a recording apparatus where the time of travel of the shock waves get recorded. Knowing the time of travel of the primary and refracted waves at various geophones, tune and distance graphs are drawn based on which it is possible to evaluate the depth of various strata in the sub soil.

Different materials such as clay, gravel, silt rock, hard

rock etc. have characteristics seismic velocities and hence it is possible to

establish their identity in the sub soil based on time distance graph.

This method is extremely useful for the determination of the

thickness of various strata and their characteristics. These surveys are useful

for obtaining preliminary information about the types and the depths of various

strata at a given site.

Limitation of the seismic methods -

- The methods cannot be used if a hard layer with a greater seismic velocity overlies a softer layer with a small seismic velocity.

- This method cannot be with for the area covered by concrete Asphalt pavement or any other artificial hard crust, having a high seismic velocity.

- If the area contains some underground features such as burned conduits, irregularly dipping strata, and irregular water table, the interpretation of the results become very difficult.

- If the surface layer is frozen, the method cannot be successfully with as it corresponds to a case of harder layer overlaying a softer layer.

- This method requires sophisticated and costly equipment.

- Proper interpretation of the seismic survey results, the services of an expert are required.

Electrical resistivity method -

This method is also known as the resistivity mapping method. This method is very rapid and economical for preliminary investigations.

This soil exploration method is based on the principle that is soil has different electrical resistivity depending upon the type of soil is water content compaction and composition. Thus, saturated soil has lower electrical resistivity as compared to loosen dry gravel or solid rocks.

To conduct the test, four electrodes, which are usually in the form of metal spikes, are driven in the ground at equal distance apart and in a straight line. The two outer electrodes are known as current electrodes. The two inner electrodes are called potential electrodes. The mean resistivity of the strata is determined by applying a DC current to the outer electrodes and by measuring the voltage drop between the inner electrodes using potentiometer. A current of 50 to 100 milli-ampere is usually supplied.

The mean resistivity is calculated by the following formula:

ρ = 2πaV/I

Where,

I = current supply

a = spacing of electrodes

V = voltage drop

The test is repeated after changing the spacing and again

determining the main resistivity up to the depth equal to the new spacing.

Average value of resistivity for various type of soil have already been established bed on tests. Thus, on knowing the values of change in mean resistivity of sub strata at site, it is possible to establish the nature and distribution of different type of soils in the formation.

This method is generally used for locating sand and gravel

deposits within a fine-grained soil deposit.

Limitation of the electrical resistivity method -

- The methods are capable of detecting only the strata having different electrical resistivity.

- The results are influenced by surface irregularities and wetness of the strata.

- The services of an expert in the field are needed.

Comments

Post a Comment

Leave your comment